For Marisa Mudge, marketing manager with Mudge Fasteners, Inc. (a supply company owned by her father), the answer is simple: “The idea of designing with limited, standard parts is absolutely brilliant because of the significant time and cost-savings it, ultimately, provides,” she says.

Although Mudge is not a design engineer, she’s worked full-time at Mudge Fasteners for more than a decade (and much longer, if you add in the time she helped her dad at the company in her adolescence). So, she knows a thing or two about fasteners.

When she met an engineer from Hewlett Packard on a plane one day — who is limited in his designs by the use of only two screws — Mudge was impressed by the company’s mandate.

“One of the biggest problems companies face related to fasteners is lost parts. Typically, fasteners are the smallest part at a job site and minimal efforts are spent tracking this inventory…so the screws or bolts get dropped at construction sites, lost on manufacturing floors, or accidentally left in pockets,” she shares. “So, a project with only two standard fastener choices would have a real advantage.”

A few lost fasteners may seem like a small problem, but replacement costs can add up quickly.

“Some standard fasteners run in excess of a dollar or two a piece,” Mudge says she often gets calls from companies that suddenly need 200 or 300 additional parts after ordering 20,000 for a job. This means a lost advantage in bulk purchasing power. “Generally, these costs are significantly higher for custom fasteners.”

What makes matters worse are the lead times. “Customized parts can take two or 20 weeks to replace, which can seriously affect project deadlines,” she says. “And most of the calls we get are not directly from the design engineers or project managers. Rather, the calls come from the workers out in the field who are under pressure to have a product manufactured or installed by a certain date. The concern is the workers may develop a work around.”

What Mudge means by “work around” is the next best solution but, possibly, not the ideal fastener for the job. “This is why it’s extremely important to consider fasteners at the design stage of a project and plan for challenges during construction, such as lost parts,” she says. “It’s also why a couple of standard fasteners per application would generally make life a lot easier.”

There are additional reasons why pre-planning is important. For example, Mudge worked with one client who insisted on fasteners that would perfectly match the color of a project’s auditorium walls — and at a guaranteed cost. “In this case, we had to provide raw, non-customized fasteners because our vendor was unable to guarantee the paint required to match that exact color.”

The reason for this was simple: the environment the fasteners would be exposed could affect the paint and color, so to guarantee it was impossible. “In such cases, the architectural aesthetics can really drive up the cost of fasteners,” she explains.

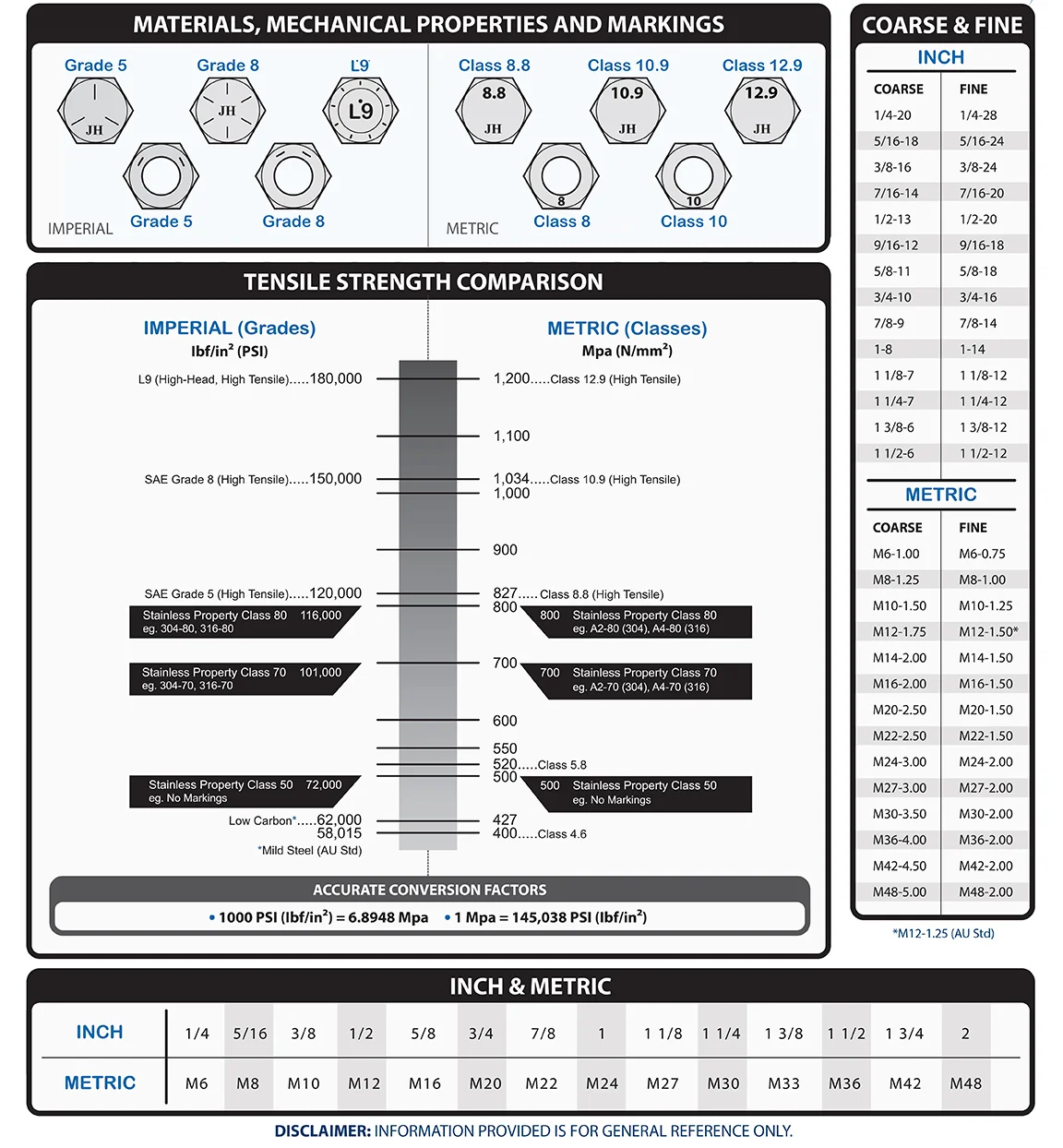

The conditions fasteners are subject to, such as moisture or high heat, can also affect their reliability. “This is where standards come in, which can sometimes be an issue with custom fasteners,” says Mudge. “Standards organizations specify and test the properties of fasteners, but there are several different organizations and standards that should be adhered to depending on the application.”

For example, the Society of Automotive Engineers or SAE is primarily focused on safety regulations for the aerospace, automotive, and commercial-vehicle industries. The American Society of Mechanical Engineers or ASME provides manufacturers with guidelines and tolerances that their bolts must conform to. (View a list of the main standards organizations at mudgefasteners.com/standards-organizations.)