Galvanized fasteners and fasteners coated with Magni or DURA-CON coating are both used to provide corrosion resistance to metal fasteners. However, there are some key differences between the two:

Composition: Galvanized fasteners are coated with a layer of zinc, either through a hot-dip galvanizing process or electroplating. The zinc coating creates a physical barrier that protects the underlying metal from corrosion. On the other hand, Magni or DURA-CON coating is a specific brand of coating that typically consists of inorganic polymers or hybrid organic-inorganic polymers. The exact composition of Magni coatings may vary depending on the specific product and application.

Corrosion Resistance: Both galvanized fasteners and Magni-coated fasteners provide corrosion resistance, but they have different levels of effectiveness in different environments. Galvanized coatings are generally suitable for moderate corrosion environments, such as dry indoor conditions or mild atmospheric exposure. Magni or DURA-CON coatings, on the other hand, are designed to offer higher levels of corrosion resistance, including resistance to harsher environments like salt spray, chemicals, and extreme temperatures.

Performance: Magni or DURA-CON coatings often provide additional benefits beyond corrosion resistance, such as improved wear resistance, enhanced adhesion, and reduced friction. These properties can be advantageous in applications where fasteners are subjected to high stress, vibration, or require low torque for assembly. Galvanized fasteners, while primarily used for corrosion protection, do not offer the same level of performance enhancements as Magni coatings.

Appearance: Galvanized fasteners have a characteristic bright, metallic appearance due to the zinc coating. Over time, the zinc coating may develop a dull gray patina as it weathers. Magni or DURA-CON coatings, on the other hand, can be formulated to provide a range of different colors and finishes, allowing for greater aesthetic flexibility.

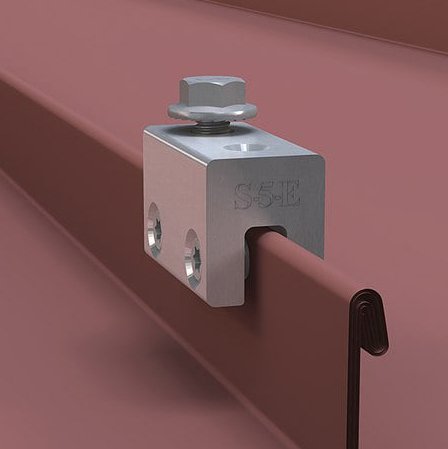

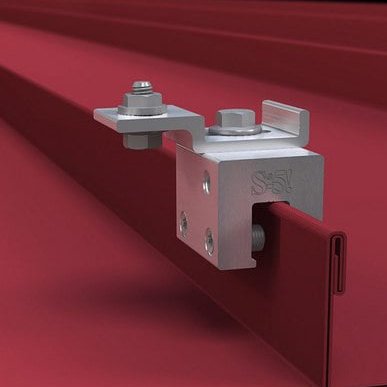

Application: Galvanized fasteners are commonly used in a wide range of general-purpose applications, including construction, automotive, and outdoor structures. Magni-coated fasteners, with their enhanced corrosion resistance and performance properties, are often preferred for more demanding applications, such as automotive components, marine equipment, and industrial machinery.

It's important to note that Magni coating is a specific brand name, and there are other coatings like DURA-CON may offer similar or different properties. When choosing between galvanized fasteners and Magni-coated fasteners, it's essential to consider the specific requirements of your application. Determining whether galvanized fasteners or Magni-coated fasteners are better depends on several factors, including the specific application, environmental conditions, and performance requirements. Here are a few considerations:

Corrosion Resistance: Magni or DURA-CON coatings generally provide higher levels of corrosion resistance compared to galvanized coatings. If your application involves exposure to harsh environments, such as saltwater, chemicals, or extreme temperatures, Magni coatings may offer superior protection against corrosion.

Performance Requirements: Magni or DURA-CON coatings often offer additional performance benefits beyond corrosion resistance. These may include improved wear resistance, enhanced adhesion, and reduced friction. If your application involves high stress, vibration, or requires low torque for assembly, Magni-coated fasteners may be more suitable.

Cost: Galvanized fasteners are generally more cost-effective compared to Magni-coated fasteners. If your project has budget constraints and does not require the advanced corrosion resistance and performance features offered by Magni coatings, galvanized fasteners may be a more economical choice.

Aesthetic Considerations: Galvanized fasteners have a distinct metallic appearance, which may be desirable in some applications. However, if you require specific colors or finishes, Magni coatings can offer greater flexibility in terms of aesthetics.

Application-Specific Factors: Consider the specific requirements and conditions of your application. Factors such as exposure to moisture, chemicals, UV radiation, temperature fluctuations, and mechanical stress should all be taken into account when selecting the appropriate fastener coating.

Ultimately, the "better" option between galvanized fasteners and Magni-coated fasteners depends on your specific needs. If you require high corrosion resistance and additional performance properties, Magni or DURA-CON coatings may be the preferred choice, albeit at a higher cost. However, if your application is in a less demanding environment and cost is a significant factor, galvanized fasteners can still provide adequate corrosion protection. It's recommended to consult with fastener suppliers or experts who can provide tailored advice based on your specific requirements.

For more information on Magni or DURA-CON coated fasteners, contact Mudge Fasteners at (800) 634-0406.