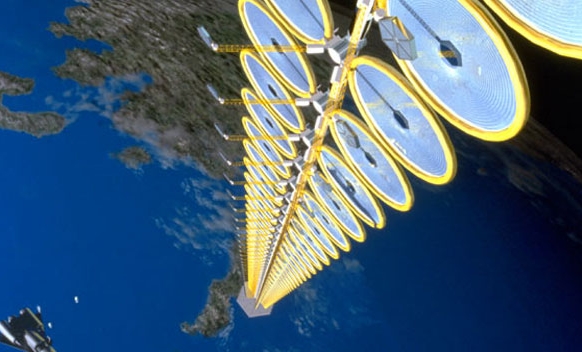

In a new report, the viability of sending solar panels into space to collect a vast quantity of uninterrupted energy has been re-investigated. Although the idea has been around since the 1970’s, space solar power has always been viewed as prohibitively expensive. In the current energy climate down here on Earth with spiraling oil prices and a massive push toward green energy sources, sending massive solar arrays into geosynchronous orbit doesn’t seem like such a strange (or expensive) idea. There are many obstacles in the way of this plan, but the international community is becoming more interested, and whoever is first to set up an orbital array will have a flexible and unlimited energy resource.

It sounds like the perfect plan: build a vast array of solar panels in space. This avoids many of the practical problems we have when building them on Earth such as land availability, poor light conditions and night time, but sending a sunlight farm into space will be expensive to set up. In the 1970’s a plan was drawn up by NASA for the possibility of orbital sunlight “harvesting”, but it was deemed too expensive with a hefty price tag of at least $1 trillion.

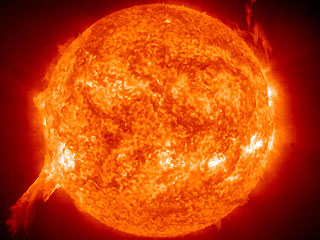

All aspects of life on this planet are affected by solar activity. The sun is constantly active and changing, and this solar variation has the ability to alter things on earth in a variety of ways. Solar variation is defined as disturbances on the sun’s surface, can include a number of things including solar storms and flares. By understanding solar activity, you can also maximize solar energy production by fine tuning your solar panels.

Understanding Solar Activity for Solar Energy Purposes

Solar variation has a great effect on solar energy generating systems. Large solar flares send out huge amounts of photons, which are the actual particles which stimulate the solar cells to generate electricity. This means that solar panels will generate more electricity in periods following large solar storms because of the increased amount of photons.

SECURING, SUPPORTING AND PROTECTING CONDUCTORS WITHIN THE PV ARRAY

PV systems are expected to have a 25-year lifespan, and array wire management solutions should match this expectancy. However, designers and installers face persistent challenges to managing free-air conductors within the PV array.

Implementing a safe, reliable and Code-compliant wire management system for exposed PV conductors is not an easy task. PV module leads can be too long or sometimes too short, requiring site-specific solutions for supporting and interconnecting the cables. Equipment grounding, PV source-circuit and inverter-output conductors from microinverters and ac modules must also be managed to ensure protection from potential damage. Within the PV array, these various conductors are often secured to module frames, support rails and other racking system components. While securing array wiring seems like it should be a straightforward exercise, the reality is that integrators continue to face numerous challenges.

Click here to read the full article from Solar Pro Magazine.

Powers Fasteners can provide a competitive advantage through price, availability and technology.

Powers Fasteners has been a worldwide pioneer in the fastening industry since 1921, and today is the leading supplier of concrete and masonry anchors and fastening systems in North America. Powers has extensive engineering and manufacturing expertise in several product groups, including mechanical anchors, adhesive anchoring systems and powered forced-entry systems such as powder-actuated and gas fastening systems.

Hilti products are often specified but can be easily substituted by an equivalent Powers product. Use the chart below to help you swap across a Hilti spec.

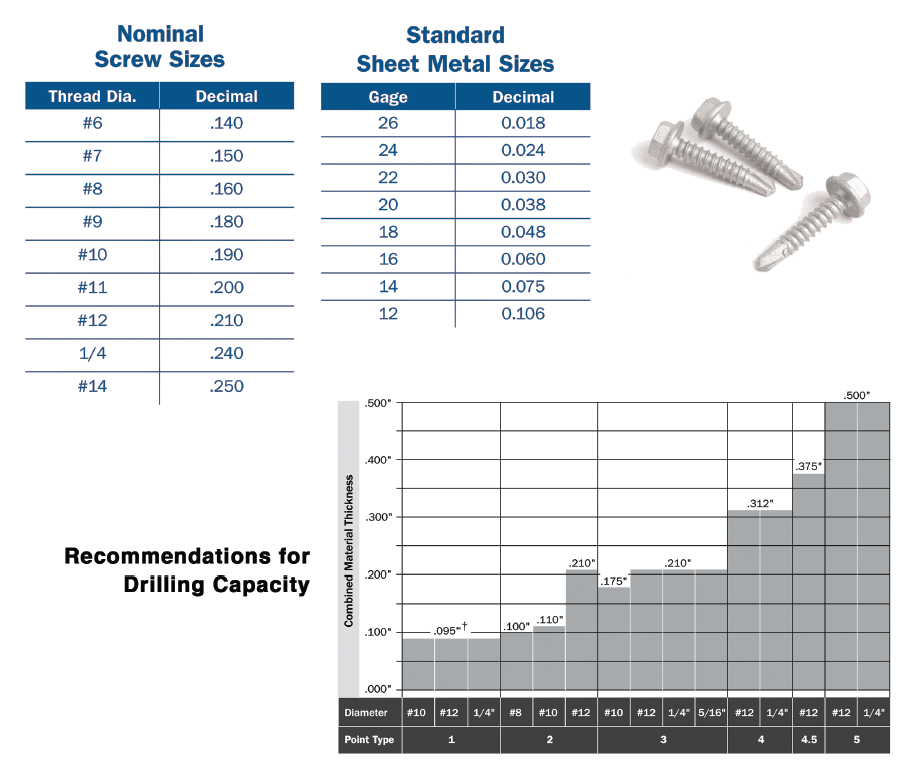

Tek® screws, are also known as self drilling screws, but are not to be confused with self-tapping or sheet metal screws which do not pre-drill. A self-drilling screw has a very small carving at the end of its tip called a drill bit. These screws drill their own hole and then tap threads to combine two or more pieces of material together without pre-drilling. This is done with nothing more than a standard power drill motor. Depending on the thickness of the material you are drilling into, you have several drill points available, the longest being a Tek 5.

Click here to download a printable PDF version of the guide to use for reference when making decisions about which drill point size is right for which fasteners for your application.

If you have any questions about self drilling screws from Mudge Fasteners, please call us at (800) 634-0406.

Zinc is naturally found in elements such as air, water, and soil as well as in plants, animals, and humans. It is the 27th most abundant element in the Earth’s crust and is infinitely recyclable without the loss of its properties, making it a true renewable resource.

Zinc’s ability to protect iron and steel products from corrosion has been known for centuries as the material has been used in construction since the second century. More than 13 million tons of zinc is produced annually worldwide—70 percent of which is from mined ores and the remaining is from recycled sources. More than half of this annual production is used in zinc coatings to protect steel from corrosion.

Click here to read the rest of the article at Construction Specifier.

Characteristics of Platings, Coatings & Finishes Chart

While we're on the topic of platings (like zinc), we'd like to offer you our downloadable Characteristics of Platings, Coatings & Finishes chart.

Click the image to the right to download a printable PDF version of the chart to use for reference when making decisions about which plating, coating or finish you should use on fasteners for your application.

Unlike most distributors, Mudge Fasteners is willing to break boxes to offer smaller quantities of Elco Construction fasteners for the convenience of our customers. No longer do you need to buy hundreds or thousands of each type of Elco fasteners, you can contact us to request a quote for just the quantities you need.

Click here to download the Elco product selection guide.

Ensuring that your employees are protected when working at heights is the business of FallTech Services Group. Fall Protection equipment will only protect a worker if they know when, where and how it is to be used. FallTech Services Group specializes in helping businesses identify fall safety hazards, write fall protection plans, engineer anchorage solutions and train employees in fall safety.

Offering a well equipped training facility with certified fall safety trainers, FSG provides a full range of in depth courses in fall protection. A balance of hands on training and classroom instruction provides the optimal fall protection training experience and course offerings ranging from entry level fall safety hazard awareness to the supervisory level competent person fall safety training. Additionally, custom fall safety courses and site specific fall protection training are available through our alternative curriculum program.

Regularly scheduled fall safety courses are available to attendees both at the FallTech Training Center in Compton, CA, a variety of regional venues throughout the United States, and at client facilities throughout North America.

FallTech Services Available

- Fall Safety Hazard Analysis

- Site Survey

- Written Job Fall Safety Analysis

- Building Plan Review

- Written Fall Protection Plans

- Jurisdictional Code Review

- Fall Safety Structural Review

- CAD Design

- Customized Fall Protection Equipment Development

- Fall Safety Anchor Point Design

Unlike most of their competitors, all FallTech products are proudly MADE IN USA.

Elco Construction recently released their new product selection guide, which clarifies what fasteners from the Flex Technology family are best for which applications.

Click here to download the selection guide, or see below for which substrate materials work best for Elco Flex Technology products.

Steel to

Steel

Dril-Flex

Bi-Flex

Tap-Flex

Steel / Aluminum Combinations

Dril-Flex

Bi-Flex

Tap-Flex

Aluminum to

Aluminum

Dril-Flex

Bi-Flex

Tap-Flex

All-Flex

Treated Wood to

Steel or Aluminum

Bi-Flex