The term “solar fasteners” is used to describe any fasteners used to install a solar power system. Typically, solar fasteners are standard parts that are used in other industries besides solar. Sometimes a solar company will design a custom fastener specific to their system. Different types of fasteners may be required depending on the method of installation.

To start; a fastener is a piece of hardware that affixes two or more objects together. Solar power design uses two broad categories of fasteners: mobile fasteners and permanent fasteners.

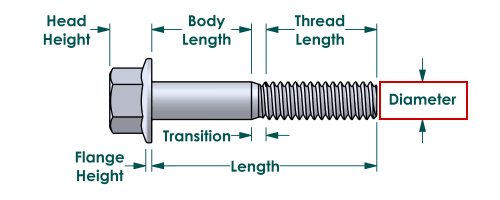

Mobile fasteners are bolts, nuts, washers, and some screws. Those fasteners are designed to create a temporary union between two objects. This temporary union means you can remove these fasteners without causing damage to the assembly. Rivets, welds, lockbolts and some screws are considered permanent fasteners, designed to create a permanent assembly between two objects. This means that if you remove one of these fasteners, you’ll cause damage to the union. The correct fastener will be dictated by the design of the solar system.

Extreme environmental conditions are frequently present at the location of a solar power installations. Solar fasteners need to be durable enough to maintain the structural integrity of a PV (photovoltaic) system. Choosing the right fastener, in right material, with the right coating, will help ensure the longevity of the joint.