What is Elco Flex Technology?

One of the most popular, and most trusted, engineered fastener brands in world is Elco Construction Fasteners. Now owned by DeWALT, Elco products are used in many different construction applications, from aluminum balcony railings to unitized curtain wall. Elco’s defining feature is their use of “Flex Technology”, offering engineers various options for ductility, strength and embrittlement resistance in fastened connections. But what is Flex Technology?

Standard fasteners are case hardened, creating vulnerabilities to delayed embrittlement failures, which are induced by hydrogen’s presence in applications involving dissimilar metal. In mixed substrates such as aluminum and steel, and with the involvement of moisture from weather conditions, galvanic reactions reduce detrimental hydrogen. The results is the destruction of a fastener’s grain boundaries, which can create sudden, and potentially very dangerous, fastener failures. In metallurgy, this reaction is known as Hydrogen Assisted Stress Corrosion Cracking (HASCC). It often occurs without typical visible clues like red rust.

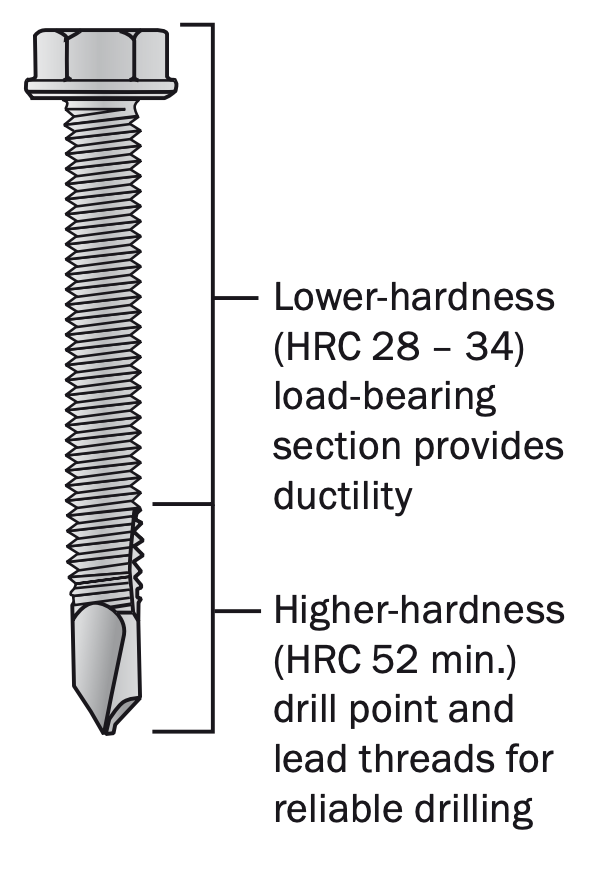

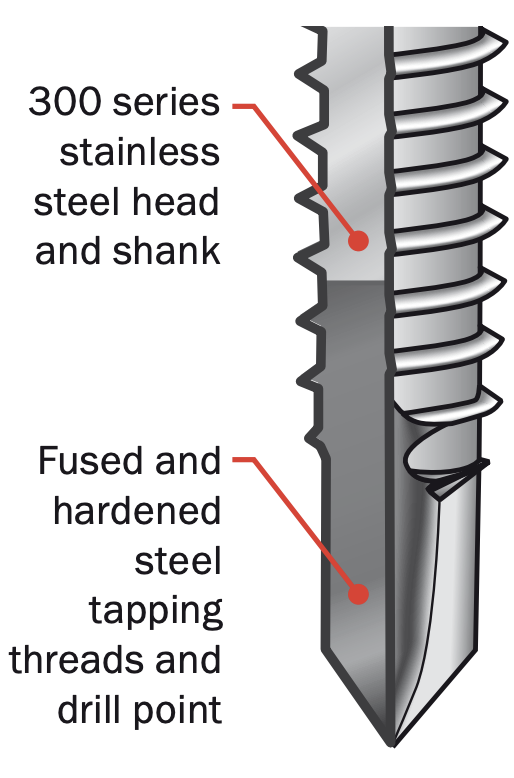

Using special alloy materials that go through proprietary heat treatments and tempering processes, Elco Construction fasteners that utilize Flex Technology far surpass any other generic fastener available in terms of resistance to hydrogen embrittlement. These fasteners allow manufacturers and engineers of systems to consider their risk and upgrade the performance of critical connections. All Elco fasteners with Flex Technology also feature Stalgard corrosion-resistant coatings. These durable, multi-layer, environmentally friendly coatings contain no chromates and silicates.

Elco’s most popular products employing Flex Technology are Alumi-Flex stainless steel drill screws, Bi-Flex self-drilling screws, ConFlex large diameter masonry screws, Dril-Flex precision engineered structural fasteners and Tap-Flex thread forming screws. Some typical applications for these products are in assemblies with dissimilar metals, building enclosures, blast protection systems and solar panel racking support systems.

For pricing or more information on Elco Flex Technology fasteners, contact Mudge Fasteners at (800) 634-0406 or buy online at FastenerExpert.us.