The short answer is NO.

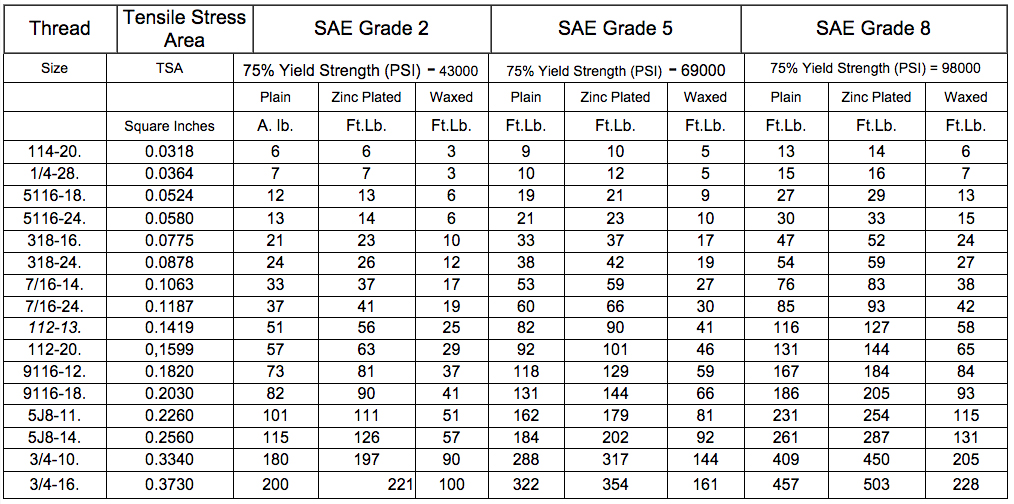

General commodity commercial fasteners do not fall under the umbrella of products that would require a UL listing or ICC-ES report. There are three main governing bodies that cover specifications for fasteners. ASTM (American Society for Testing and Materials) covers primarily bolts and fasteners for construction applications. SAE (Society of Automotive Engineers) covers fasteners for automotive, machinery, and OEM applications. ASME (American Society of Mechanical Engineers) standards B18.2.1 and B18.2.1 cover dimensional tolerances for square and hex head bolts, screws, and nuts. Mudge Fasteners provides fasteners to these three sets of specifications (ASTM, SAE, and ASME). A fourth specification group that is also applicable is AASHTO (American Association of State Highway & Transportation Officials). AASHTO specifications are typically only called out on highway projects and many AASHTO designations can be directly converted to an ASTM equivalent.

ICC (International Code Council) is the primary governing body responsible for writing and maintaining building, plumbing, mechanical, and fire codes adopted by local and state municipalities, and the federal government. ICC-ES (International Code Council-Evaluation Services, Inc.) is the branch of ICC responsible for performing technical evaluations of building products, components, methods, and materials to ensure that they meet the requirements of the codes. This evaluation process culminates in an ICC-ES report that provides evidence that the evaluated product or system meets code requirements. However, in the case of most anchor bolts and fasteners, the applicable sections of the codes (International Building Code, International Residential Code, International Property Maintenance Code, Etc.) direct you to the ASTM specifications covering said anchor bolts or fasteners. As the ASTM specifications already cover anchor bolts and fasteners in detail, there is no reason for ICC to write their own specifications for these items. For the same reason, ICC-ES does not need to perform evaluation testing of anchor bolts or fasteners. As long as the bolts meet the applicable ASTM specification(s), they will meet the applicable Code section(s).

UL Listings are a service provided by Underwriters Laboratories Inc (UL). Manufacturers submit products to UL for testing and safety certification on a voluntary basis. There are no laws specifying that a product must be tested and given a UL Mark. While there are many municipalities that have laws, codes or regulations which require a product to be tested by a nationally recognized testing laboratory (such as UL) before that product can be used within their jurisdiction, anchor bolts and fasteners are typically not among these products. This is for two reasons; the first being that products required to be tested and receive a UL Listing are typically potentially hazardous products, including marine products, life saving devices, fire suppression and containment products, chemicals, and industrial, mechanical and automotive equipment. The second reason is that, just as with ICC-ES, the ASTM specifications already cover bolts and fasteners in depth, and it would be redundant to re-cover the same information.

In summation, as long as a bolt or fastener is manufactured to the correct ASTM, SAE, ASME, and/or AASHTO specification, there is no need for it to be tested or evaluated by ICC-ES, UL, or other similar listing services. When you purchase from Mudge Fasteners, you can request a complete certification package, ensuring that your product meets the applicable specification(s).