Your Trusted Source for Elco Fasteners

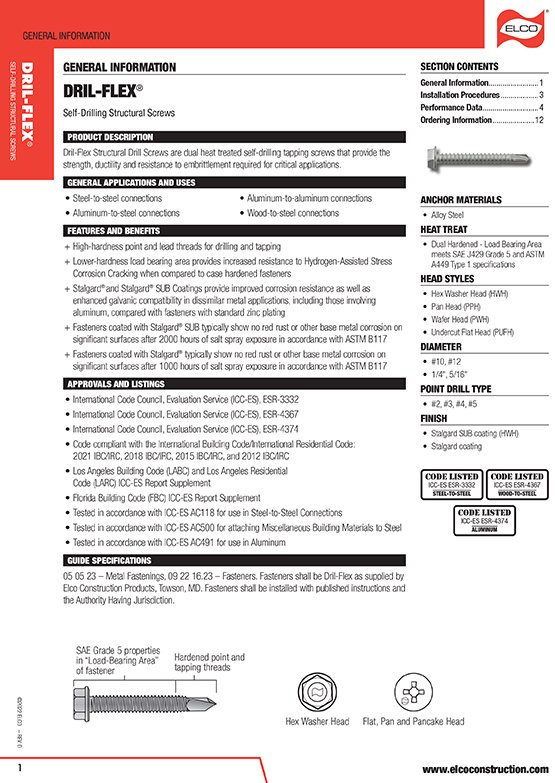

Elco Construction Fasteners has developed a family of products that utilize Flex Technology to incorporate high performance and virtual immunity to delayed embrittlement failures. Using special alloy materials that receive proprietary heat treatments and tempering processes, the Flex Technology line of products far surpasses any standard fastening format available. Flex Technology allows designers and system manufacturers to manage their risk and enhance the performance of critical connections.

Download the Flex Technology brochure • Download the Elco product selection guide

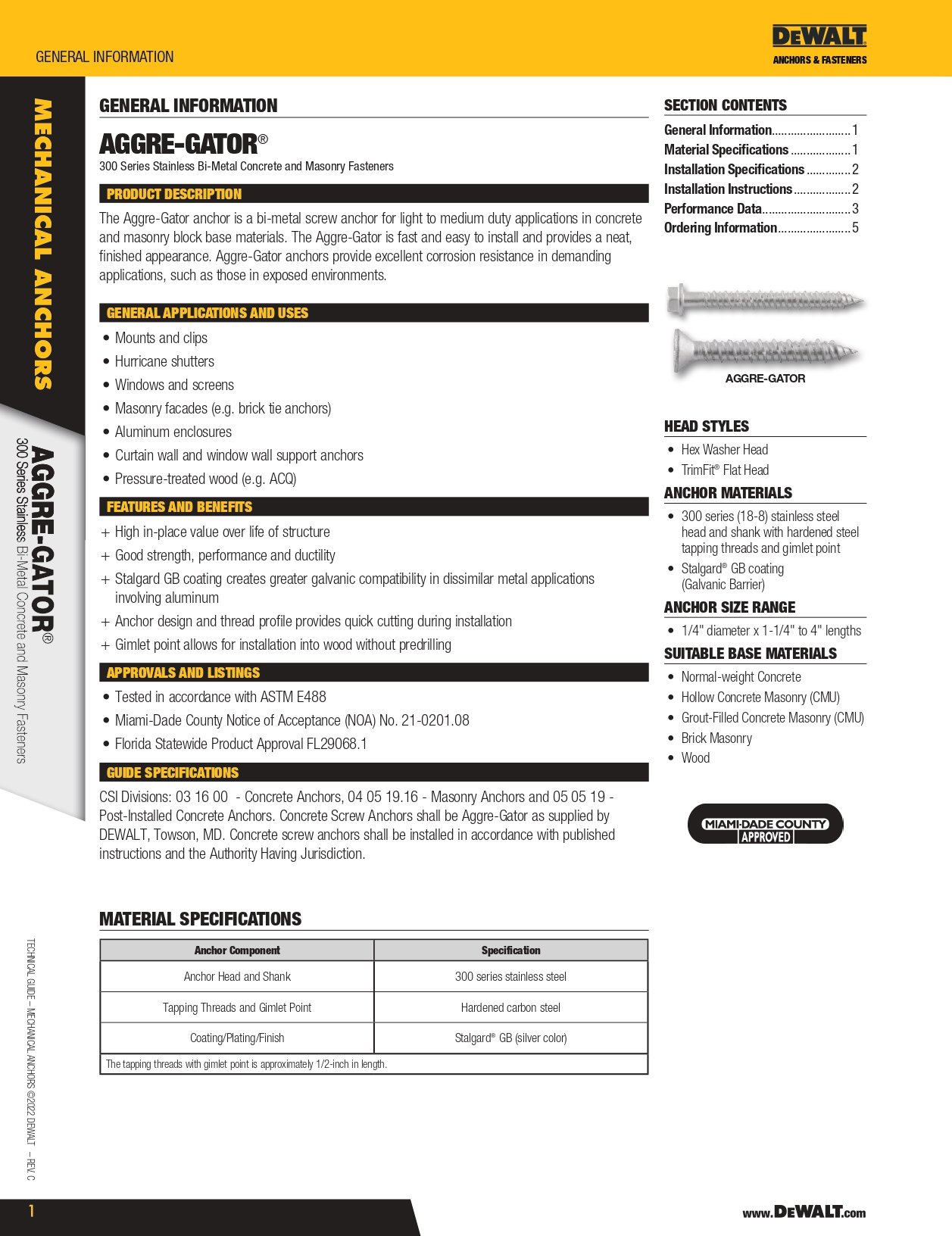

Elco Aggre-Gator Fasteners

Bi-Metal Fasteners: The corrosion resistance of 300 series stainless steel in a threaded concrete anchor.

Elco Bi-Flex Fasteners

Bi-Flex extended warranties and sustainable materials add up to greater expectations for performance of all building components.

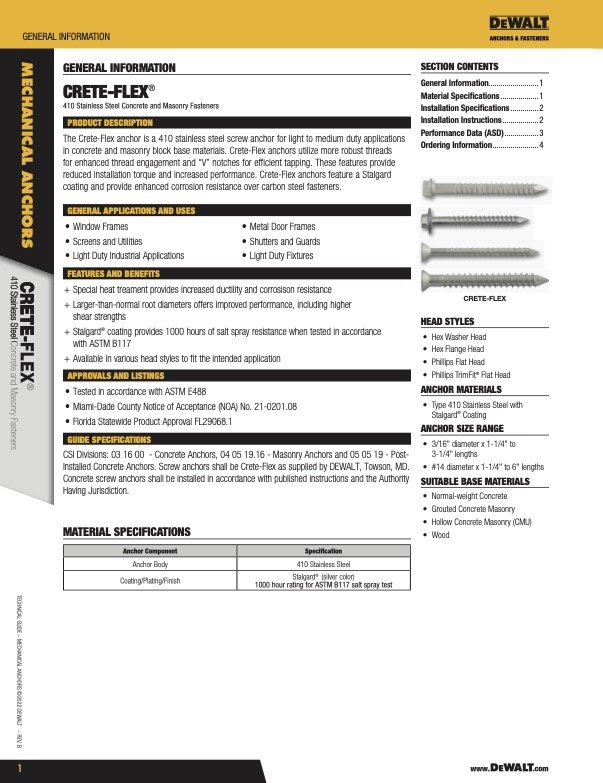

Elco Crete-Flex Fasteners

High performance, 410 stainless steel masonry anchors deliver corrosion resistance, installation consistency and outstanding performance.

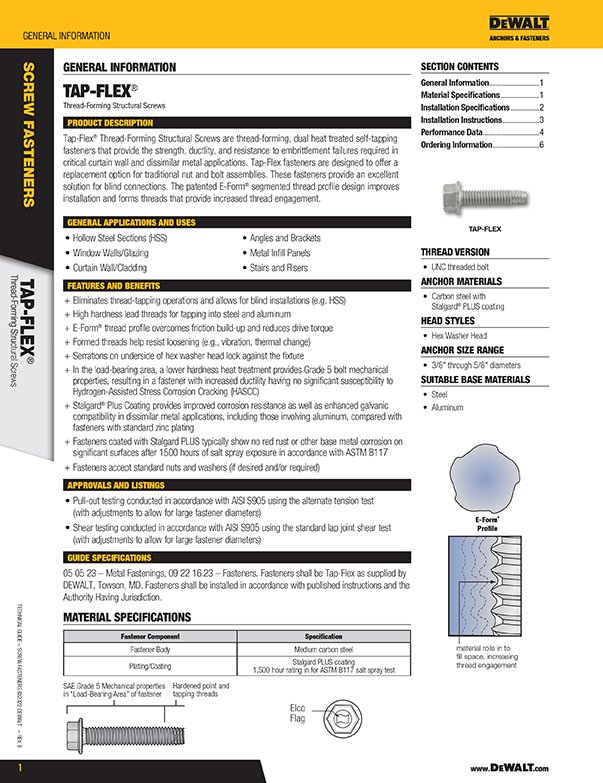

Elco Tap-Flex Fasteners

These thread-forming screws are dual heat treated, self-tapping fasteners that provide the strength, ductility, and resistance to embrittlement failures required in critical curtain wall and dissimilar metal applications.